1. Current Situation

1. Current Situation

For high-speed railways with ballasted tracks, precision measurement and tamping operations can obtain accurate mileage based on the control network and the designed track alignment. During these operations, the measurement trolley and tamping machine's mileage systems are segmented and corrected based on the precise mileage system to achieve the desired precision measurement and tamping effects.

In the early days, the control networks of conventional railways were either ineffective or incomplete. The only reference available on-site was the mileage stakes. After long-term maintenance and replacement, the accuracy of these stakes has significantly deteriorated. Measurement trolleys often do not match the on-site mileage stakes or fail to meet the requirements for precision measurement and tamping. This is especially true at the boundaries between sections (e.g., between workshops), where there can be discrepancies of several meters or even tens of meters in mileage, which affects the precision of measurement and tamping operations.

2. Solutions

To address the issue of non-unified mileage in precision measurement and tamping operations for conventional railways, the following solutions are proposed to achieve better operational results.

Note: For precision measurement and tamping applications, mileage can be understood as a special reference point, which can either match the on-site mileage stakes or be an independent counting system unrelated to the site. However, both precision measurement and tamping operations must use the same system to achieve optimal results.

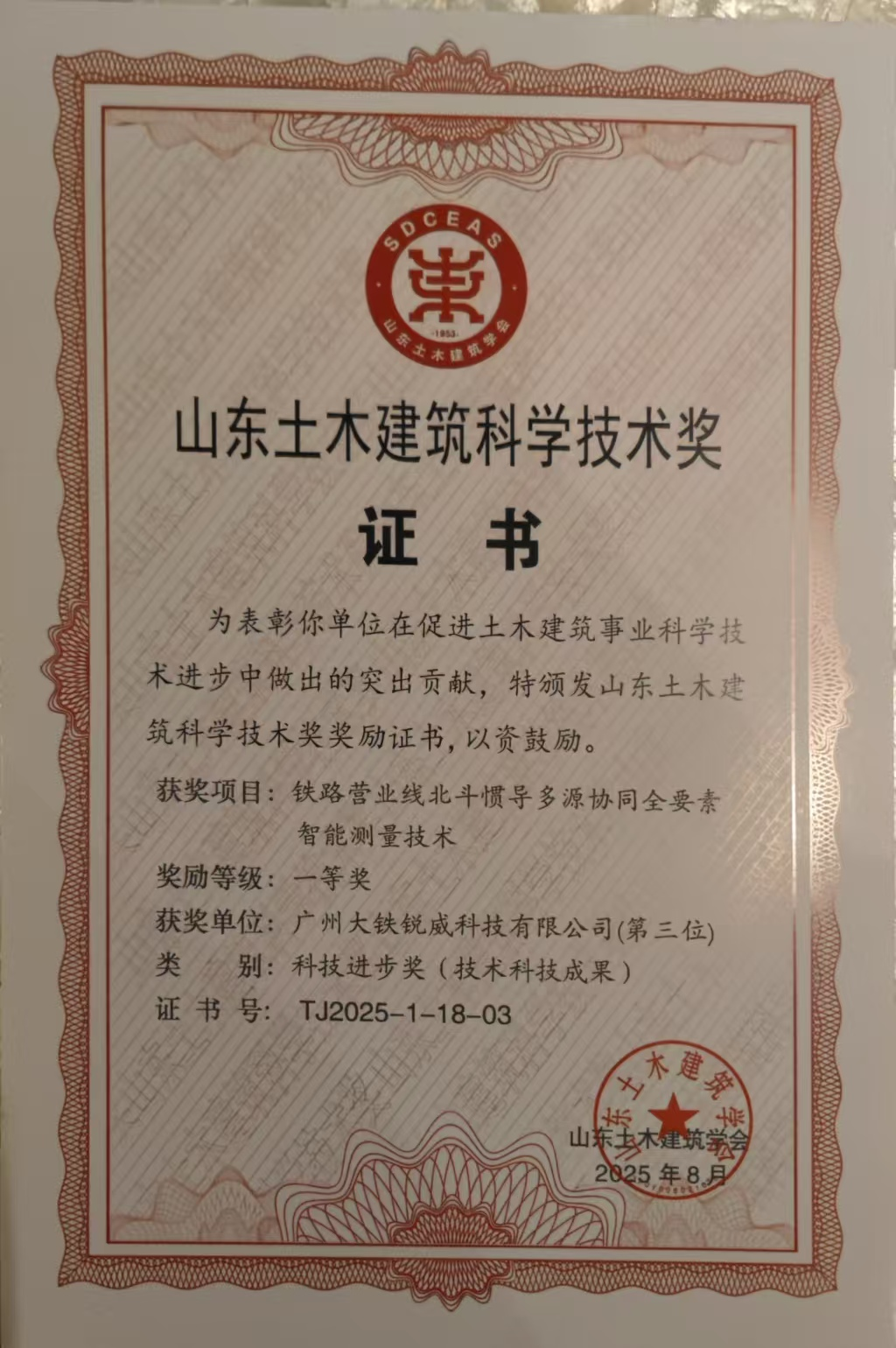

2.1 Solution One: Constructing a Beidou Reference Station Network

The National Railway Group's issued the "Guiding Opinions on Precision Measurement and Tamping of Conventional Railways" (National Railway Group's [2021] No. 4) and related guidance documents, which clearly outline the technical solution for constructing a Beidou reference station network. This solution uses Beidou + inertial navigation fusion technology to completely solve the precision measurement problem in conventional railways.

The mileage system discussed in this article can use RTK technology to convert the track centerline coordinates under the Beidou reference station network into route mileage. This mileage serves as a unique identifier and is marked on-site as the sole basis for precision measurement and tamping operations.

图 1 基于北斗基准站网精准放样百米标

2.2 Solution Two: Using On-site Mileage Stakes as the Benchmark

During track precision measurement operations, the mileage is verified every 100m or 200m. When the difference between the measurement trolley and the on-site mileage stakes does not exceed the length of one sleeper, the measurement trolley's counting system is directly corrected based on the on-site mileage stakes (especially kilometer stakes). When the difference is significant, a measuring tape is used to check against the last corrected mileage stake to determine the cause of the discrepancy. If the mileage stakes are incorrect, the measurement trolley's counting system is used as the basis for self-correction. This process is repeated to control the on-site mileage system error within a range of 100m or 200m. During large-scale machine tamping operations, the on-site mileage stakes are also used as the benchmark to regularly correct the counting system, ensuring that the measurement points and tamping points are unified.

图 2 以现场里程桩为基准

Note: The intervals of 100m or 200m are chosen based on a comprehensive consideration of operational efficiency and mileage correction effectiveness.

2.3 Solution Three: Using the Measurement Trolley's Counting System as the Benchmark

When the accuracy of the on-site mileage stakes is unreliable or does not meet the requirements for precision measurement and tamping, a solution based on the measurement trolley's counting system can be adopted. During track precision measurement operations, a mileage stake or mark is selected at the starting point of the track to be measured, and its mileage is determined (it is recommended to maintain a correlation with the original track mileage). Operations are carried out in sequence, either in the direction of increasing or decreasing mileage, and unified paint marks are left every 100m or 200m on-site as references for large-scale machine tamping operations. This ensures that the measurement points and tamping points are unified.

图 3 以测量小车计程系统为基准

3. Comparative Analysis of Advantages

The three solutions mentioned in this article all have their applicable scenarios. Considering the comprehensive factors of operational effectiveness, maintenance costs, measurement efficiency, and potential for expansion, the following comparative analysis is provided:

No. | Solution Name | perational Effectiveness | Maintenance Costs | Measurement Efficiency | Potential for Expansion | Notes |

1 | Constructing a Beidou Reference Station Network | Excellent | High | High | Significant | Completely solves the maintenance benchmark issue |

2 | Using On-site Mileage Stakes as the Benchmark | Many internal chain breaks | High | Frequent corrections required | None | For maintaining the status quo |

3 | Using the Measurement Trolley's Counting System as the Benchmark | Good | None | Frequent marking required | None | For temporary use in small areas |

Conclusion:

(1) For lines where the operating speed does not meet the conditions for network construction, the existing mileage markers and curve characteristic point markers should be determined and ensured to be accurate, based on the on-site mileage stakes, as the basis for maintenance.

(2) Where the control network layout is feasible, a Beidou reference station network should be constructed according to the standards. The track centerline coordinates should be matched and integrated with the designed track inventory to digitize the track. Using RTK technology, the track mileage table, horizontal curve characteristic points, and the start and end points of vertical curves should be precisely located as the basis for maintenance to achieve better operational results.

(3) When the accuracy of the on-site mileage benchmark is insufficient or for small-scale track maintenance, the measurement trolley's counting system can be used as the basis for temporary matching of precision measurement and tamping operations.